National Service Hotline :+86-0537-7537399

The annual treatment capacity of NdFeB waste reaches 20000 tons, which is at the leading level in China.

Tianma has its own raw material procurement team, relying on the unique technology of rapid on-site identification of raw material quality, and has mature raw material channels to ensure raw material supply.

Flexible and controllable business model, free from market price fluctuations.

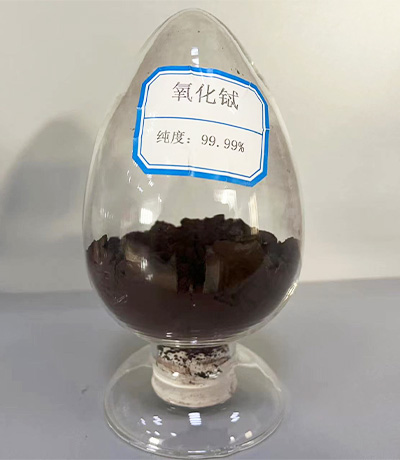

Terbium oxide is a brown powdery solid, which is mainly used in green fluorescent materials such as trichromatic fluorescent lamps, projection televisions, X-ray sensitizing screens, electroluminescent materials, plasma plane displays, biological fluorescent probes, Faraday optical isolation materials for lasers and optoelectronic devices, neodymium iron boron permanent magnet alloy additives, giant magnetostrictive materials, magneto-optical materials Nonferrous metal additives, etc.

A. Raw material preparation

The raw materials are roughly processed by crushing and ball milling, the advanced high-efficiency and energy-saving grinding equipment in the industry is adopted, the mechanical dust-free transportation and fine processing are carried out, and finally the qualified oxidized materials are prepared by oxidative roasting.

B. Optimal solution extraction

The patented technology developed by the company is applied to extract rare earth and high price elements from raw materials, low acid leaching, countercurrent efficient washing, accurate and excellent dissolution and impurity removal, and prepare high-quality extraction and separation material liquid.

C. Extraction separation

Combined with the characteristics of valuable elements in NdFeB waste industry, the company has developed and applied the self-developed full linkage fuzzy extraction technology to extract and separate praseodymium (PR), neodymium (nd), gadolinium (GD), terbium (TB), dysprosium (Dy), holmium (HO) cobalt (CO) and other intermediate products. Process characteristics have the advantages of stable product quality, high purity, low cost and easy standardized operation.

D. Precipitation burning

High quality synthetic oxalic acid is used to precipitate and transform various products extracted and separated by special equipment. The physical and chemical indexes of the products are higher than those of similar products in the industry. The self-designed rotary automatic production line is used for burning, and the market is in short supply.